ООО "MELZ" is a manufacturing company. The production capacity of the plant allows to produce almost all mechanical operations for working with metal and other materials.

Our plant has a full production cycle which consists of: premachining installation, stamping area, machining area, techno-chemical area, electro-optical systems assembly area for electron-beam tubes, flat tubes production area, Assembly area.

Different types of materials are used in the manufacture:

- Metal: stainless steel, 08Х18Н10, 12Х18Н10, 29НК, 38НКД, 47НХР, oxygen-free copper (OFC);

- Glass:С52-1, С93-1, С93-3;

All of the production areas mentioned above are located in the detached facility more than 3200 sq. m in area.

Premachining installation

At this production area the strip clipping is done by the circle shears; cut thicknessis 0,1 m to 2mm, width starts at 2,5 mm; there’s a flexible system of knife sets for strips of any thickness

Equipment used:

- Circle shears;

- Wire and copper strip rolls;

- Grinders and glass polishing machines;

- Glass-cutting machines.

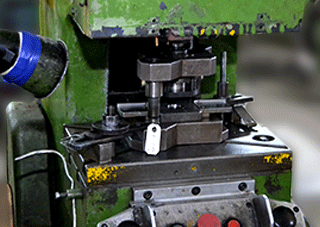

Stamping area

Parts stamping for cathode-ray tubes, image-converter tubes, photomultipliers and other stampings is performed by highly skilled professionals with great precision.

Equipment used

- Toggle presses with the following pulling force:

1,5-6,3 — 12 items

16 – 10 items;

40– 3 items;

63 – 1 items;

20 (hydraulic press) – 1 item; - Express benders А-6111, А-6112 – 5 items;

- Automatic molding machines Sz-215 – 1 item; Sz-230 – 4 items;

Machining area

High precision mechanical parts are produced at this production area.

Equipment used

- Surface grinder

- Milling machines

- Lathe machines

- CNC machines

Techno-chemical area

Chemical treatment of metals is performed at this area:

- Degreasing

- Pickling;

- Metal coating (nickel coating, zinc coating, chemical oxidation, anodic oxidation);

- Electropolishing, chemical polishing of stainless steel;

Electro-optical systems assembly area for electron-beam tubes.

Equipment used

- Cutting tables (electric resistance welding)

Flat tubes production area

Our plant produces over 20 types of flat tubes for different kinds of vacuum tubes.

Equipment used

- Semi-automatic machines 24-spindle – 3 items;

- Personal stamping machine

Assembly area

Equipment used

- Eight-position exhaust unit;

- Personal units for different types of cathode-ray tubes;